SNAP 8 was the first reactor designed with these space stations in mind in mind. While SNAP-10A was a low-power system (at 500 watts when flown, later upgraded to 1 kW), and SNAP-2 was significantly larger (3 kW), there was a potential need for far more power. Crewed space stations take a lot of power (the ISS uses close to 100 kWe, as an example), and neither the SNAP-10 or the SNAP-2 were capable of powering the space stations that NASA was in the beginning stages of planning.

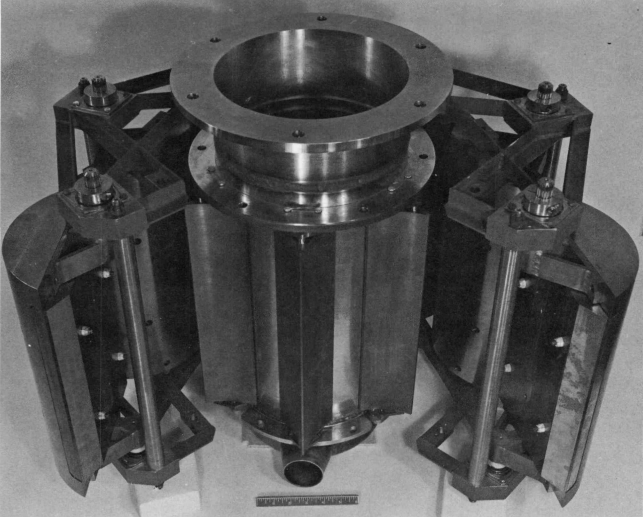

Initially designed to be far higher powered, with 30-60 kilowatts of electrical power, this was an electric supply that could power a truly impressive outpost for humanity in orbit. However, the Atomic Energy Commission and NASA (which was just coming into existence at the time this program was started) didn’t want to throw the baby out with the bath water, as it were. While the reactor was far higher powered than the SNAP 2 reactor that we looked at last time, many of the power system’s components are shared: both use the same fuel (with minor exceptions), both use similar control drum structures for reactor control, both use mercury Rankine cycle power conversion systems, and perhaps most attractively both were able to evolve with lessons learned from the other part of the program.

While SNAP 8 never flew, it was developed to a very high degree of technical understanding, so that if the need for the reactor arose, it would be available. One design modification late in the SNAP 8 program (when the reactor wasn’t even called SNAP 8 anymore, but the Reference Zirconium Hydride Reactor) had a very rare attribute in astronuclear designs: it was shielded on all sides for use on a space station, providing more than twice the electrical power available to the International Space Station without any of the headaches normally associated with approach and docking with a nuclear powered facility.

Let’s start back in 1959, though, with the SNAP 8, the first nuclear electric propulsion reactor system.

SNAP 8: NASA Gets Involved Directly

The SNAP 2 and SNAP 10A reactors were both collaborations between the Atomic Energy Commission (AEC), who were responsible for the research, development, and funding of the reactor core and primary coolant portions of the system, and the US Air Force, who developed the secondary coolant system, the power conversion system, the heat rejection system, the power conditioning unit, and the rest of the components. Each organization had a contractor that they used: the AEC used Atomics International (AI), one of the movers and shakers of the advanced reactor industry, while the US Air Force went to Thompson Ramo Wooldridge (better known by their acronym, TRW) for the SNAP-2 mercury (Hg) Rankine turbine and Westinghouse Electric Corporation for the SNAP-10’s thermoelectric conversion unit.

1959 brought NASA directly into the program on the reactor side of things, when they requested a fission reactor in the 30-60 kWe range for up to one year; one year later the SNAP-8 Reactor Development Program was born. It would use a similar Hg-based Rankine cycle as the SNAP-2 reactor, which was already under development, but the increased power requirements and unique environment that the power conversion system necessitated significant redesign work, which was carried out by Aerojet General as the prime contractor. This led to a 600 kWe rector core, with a 700 C outlet temperature As with the SNAP-2 and SNAP-10 programs, the SNAP 8’s reactor core was funded by the AEC, but in this case the power conversion system was the funding responsibility of NASA.

The fuel itself was similar to that in the SNAP-2 and -10A reactors, but the fuel elements were far longer and thinner than those of the -2 and -10A. Because the fuel element geometry was different, and the power level of the reactor was so much higher than the SNAP-2 reactor, the SNAP-8 program required its own experimental and developmental reactor program to run in parallel to the initial SNAP Experimental and Development reactors, although the materials testing undertaken by the SNAP-2 reactor program, and especially the SCA4 tests, were very helpful in refining the final design of the SNAP-8 reactor.

The power conversion system for this reactor was split in two: identical Hg turbines would be used, with either one or both running at any given time depending on the power needs of the mission. This allows for more flexibility in operation, and also simplifies the design challenges involved in the turbines themselves: it’s easier to design a turbine with a smaller power output range than a larger one. If the reactor was at full power, and both turbines were used, the design was supposed to produce up to 60 kW of electrical power, while the minimum power output of a single turbine would be in the 30 kWe range. Another advantage was that if one was damaged, the reactor would continue to be able to produce power.

Due to the much higher power levels, an extensive core redesign was called for, meaning that different test reactors would need to be used to verify this design. While the fuel elements were very similar, and the overall design philosophy was operating in parallel to the SNAP-2/10A program, there was only so much that the tests done for the USAF system would be able to help the new program. This led to the SNAP-8 development program, which began in 1960, and had its first reactor, the SNAP-8 Experimental Reactor, come online in 1963.

After the S8ER testing concluded, a mockup reactor, the SNAP-8 Development Mockup, was built based on the 1962 version of the design. This mockup never underwent nuclear testing, but was used for extensive non-nuclear testing of the designs components. Basically, every component that could be tested under non-nuclear conditions (but otherwise identical, including temperature, stress loading, vacuum, etc.) was tested and refined with this mockup. The tweaks to the design that this mockup suggested are far more minute than we have time to cover here, but it was an absolutely critical step to preparing the SNAP-8 reactor’s systems for flight test.

SNAP-8 Development Reactor: Facing Challenges with the Design

The final reactor in the series, the SNAP-8 Development Reactor, was a shorter-lived reactor, in part because many of the questions that needed to be answered about the geometry had been answered by the S8ER, and partly because the unanswered materials questions were able to be answered with the SCA4 reactor. This reactor underwent dry critical testing in June 1968, and power testing began at the beginning of the next year. From January 1969 to December 1969, when the reactor was shut down for the final time, the reactor operated at nominal (600 kWt) power for 668 hours, and operated at 1000 kWt for 429 hours.

However, a variety of difficulties, including with the power conversion system, the different neutronic environment of the core geometry compared to the SNAP 2/10A core, and other difficulties made this reactor look like too much of a bother in its current configuration, but a lot of promising results had come out at the same time.

One way or the other, NASA was looking for something different out of the reactor system, and this led to many changes. Rather than an electric propulsion system, focus shifted to a crewed space station, which has different design requirements, most especially in shielding. In fact, the reactor was split into three designs, none of which kept the SNAP name (but all kept the fuel element and basic core geometry).

A New Life: the Children of SNAP-8

Even as the SNAP-8 Development Reactor was undergoing tests, the mission for the SNAP-8 system was being changed. This would have major consequences for the design of the reactor, its power conversion system, and what missions it would be used in. These changes would be so extensive that the SNAP-8 reactor name would be completely dropped, and the reactor would be split into four concepts.

The first concept was the Space Power Facility – Plumbrook (SPT) reactor, which would be used to test shielding and other components at NASA’s Plum Brook Research Center outside Cleveland, OH, and could also be used for space missions if needed. The smallest of the designs (at 300 kWt), it was designed to avoid many of the problems associated with the S8ER and S8DR; however, funding was cut before the reactor could be built. In fact, it was cut so early that details on the design are very difficult to find.

The second reactor, the Reactor Core Test, was very similar to the SPF reactor, but it was the same power output as the nominal “full power” reactor, at 600 kWt. Both of these designs increased the number of control drums to eight, and were designed to be used with a traditional shadow shield. Neither of them were developed to any great extent, much less built.

A third design, the 5 kWe Thermoelectric Reactor, was a space system, meant to take many of the lessons from the SNAP-8 program and apply them to a medium-power system which would apply both the lessons of the SNAP-8 ER and DR as well as the SNAP-10A’s experience with thermoelectric power conversion systems to a reactor between the SNAP-10B and Reference Zirconium Hydride reactor in power output.

The final design, the Reference Zirconium Hydride Reactor (ZrHR), was extensively developed, even if geometry-specific testing was never conducted. This was the most direct replacement for the SNAP-8 reactor, and the last of the major U-ZrH fueled space reactors in the SNAP program. Rather than powering a nuclear electric spacecraft, however, this design was meant to power space stations.

The Stations: Orbital Missions for SNAP-8 Reactors

At the time of the redesign, three space stations were being proposed for the near future: the first, the Manned Orbiting Research Laboratory, (later changed to the Manned Orbiting Laboratory, or MOL), was a US Air Force project as part of the Blue Gemini program. Primarily designed as a surveillance platform, advances in photorecoinnasance satellites made this program redundant after just a single flight of an uncrewed, upgraded Gemini capsule.

The second was part of the Apollo Applications Program. Originally known as the Saturn V Orbital Workshop (OWS), this later evolved into Skylab. Three crews visited this space station after it was launched on the final Saturn V, and despite huge amounts of work needed to repair damage caused during a particularly difficult launch, the scientific return in everything from anatomy and physiology to meteorology to heliophysics (the study of the Sun and other stars) fundamentally changed our understanding of the solar system around us, and the challenges associated with continuing our expansion into space.

The final space station that was then under development was the Modular Space Station, which would in the late 1980s and early 1990s evolve into Space Station Freedom, and at the start of its construction in 1998 (exactly 20 years ago as of the day I’m writing this, actually) was known as the International Space Station. While many of the concepts from the MSS were carried over through its later iterations, this design was also quite different from the ISS that we know today.

Because of this change in mission, quite a few of the subsystems for the power plant were changed extensively, starting just outside the reactor core and extending through to shielding, power conversion systems, and heat rejection systems. The power conversion system was changed to four parallel thermoelectric convertors, a more advanced setup than the SNAP-10 series of reactors used. These allowed for partial outages of the PCS without complete power loss. The heat rejection system was one of the most mission-dependent structures, so would vary in size and configuration quite a bit from mission to mission. It, too, would use NaK-78 as the working fluid, and in general would be 1200 (on the OWS) to 1400 (reference mission) sq. ft in surface area. We’ll look more at these concepts in later posts on power conversion and heat rejection systems, but these changes took up a great deal of the work that was done on the ZrHR program.

One of the biggest reasons for this unusual shielding configuration was to allow a compromise between shielding mass and crew radiation dose. In this configuration, there would be three zones of radiation exposure: only shielded by the 4 pi shield during rendezvous and docking (a relatively short time period) called the rendezvous zone; a more significant shielding for the spacecraft but still slightly higher than fully shielded (because the spacecraft would be empty when docked the vast majority of the time) called the scatter shield zone; and the crewed portion of the space station itself, which would be the most shielded, called the primary shielded zone. With the 4 pi shield, the entire system would mass 24,450 pounds, of which 16,500 lbs was radiation shielding, leading to a crew dose of between 20 and 30 rem a year from the reactor.

The mission planning for the OWS was flexible in its launch configuration: it could have launched integral to the OWS on a Saturn V (although, considering the troubles that the Skylab launch actually had, I’m curious how well the system would have performed), or it could have been launched on a separate launcher and had an upper stage to attach it to the OWS. The two options proposed were either a Saturn 1B with a modified Apollo Service Module as a trans-stage, or a Titan IIIF with the Titan Trans-stage for on-orbit delivery (the Titan IIIC was considered unworkable due to mass restrictions).

After the 3-5 years of operational life, the reactor could be disposed of in two ways: either it would be deorbited into a deep ocean area (as with the SNAP-10A, although as we saw during the BES-5’s operational history this ended up not being considered a good option), or it could be boosted into a graveyard orbit. One consideration which is very different from the SNAP-10A is that the reactor would likely be intact due to the 4 pi shield, rather than burning up as the SNAP-10A would have, meaning that a terrestrial impact could lead to civilian population exposures to fission products, and also having highly enriched (although not quite bomb grade) uranium somewhere for someone to be able to relatively easily pick up. This made the deorbiting of the reactor a bit pickier in terms of location, and so an uncontrolled re-entry was not considered. The ideal was to leave it in a parking orbit of at least 400 nautical miles in altitude for a few hundred years to allow the fission products to completely decay away before de-orbiting the reactor over the ocean.

Nuclear Power for the Moon

The final configuration that was examined for the Advanced ZrH Reactor was for the lunar base that was planned as a follow-on to the Apollo Program. While this never came to fruition, it was still studied carefully. Nuclear power on the Moon was nothing new: the SNAP-27 radioisotope thermoelectric generator had been used on every single Apollo surface mission as part of the Apollo Lunar Surface Experiment Package (ALSEP). However, these RTGs would not provide nearly enough power for a permanently crewed lunar base. As an additional complication, all of the power sources available would be severely taxed by the 24 day long, incredibly cold lunar night that the base would have to contend with. Only nuclear fission offered both the power and the heat needed for a permanently staffed lunar base, and the reactor that was considered the best option was the Advanced ZrH Reactor.

The configuration of this form of the reactor was very different. There are three options for a surface power plant: the reactor is offloaded from the lander and buried in the lunar regolith for shielding (which is how the Kilopower reactor is being planned for surface operations); an integral lander and power plant which is assembled in Earth (or lunar) orbit before landing, with a 4 pi shield configuration; finally an integrated lander and reactor with a deployable radiator which is activated once the reactor is on the surface of the moon, again with a 4 pi shield configuration. There are, of course, in-between options between the last two configurations, where part of the radiator is fixed and part deploys. The designers of the ZrHR decided to go with the second option as their best design option, due to the ability to check out the reactor before deployment to the lunar surface but also minimizing the amount of effort needed by the astronauts to prepare the reactor for power operations after landing. This makes sense because, while on-orbit assembly and checkout is a complex and difficult process, it’s still cheaper in terms of manpower to do this work in Earth orbit rather than a lunar EVA due to the value of every minute on the lunar surface. If additional heat rejection was required, a deployable radiator could be used, but this would require flexible joints for the NaK coolant, which would pose a significant materials and design challenge. A heat shield was used when the reactor wasn’t in operation to prevent exessive heat loss from the reactor. This eased startup transient issues, as well as ensuring that the NaK coolant remained liquid even during reactor shutdown (frozen working fluids are never good for a mechanical system, after all). The power conversion system was exactly the same configuration as would be used in the OWS configuration that we discussed earlier, with the upgraded, larger tubes rather than the smaller, more numerous ones (we’ll discuss the tradeoffs here in the power conversion system blog posts).

This power plant would end up providing a total of 35.5 kWe of conditioned (i.e. usable, reliable power) electricity out of the 962 kWt reactor core, with 22.9 kWe being delivered to the habitat itself, for at least 5 years. The overall power supply system, including radiator, shield, power conditioning unit, and the rest of the ancillary bits and pieces that make a nuclear reactor core into a fission power plant, ended up massing a total of 23,100 lbs, which is comfortably under the 29,475 lb weight limit of the lander design that was selected (unfortunately, finding information on that design is proving difficult). A total dose rate at a half mile for an unshielded astronaut would be 7.55 mrem/hr was considered sufficient for crew radiation safety (this is a small radiation dose compared to the lunar radiation environment, and the astronauts will spend much of their time in the much better shielded habitat.

Sadly, this power supply was not developed to a great extent (although I was unable to find the source document for this particular design: NAA-SR-12374, “Reactor Power Plants for Lunar Base Applications, Atomics International 1967), because the plans for the crewed lunar base were canceled before much work was done on this design. The plans were developed to the point that future lunar base plans would have a significant starting off point, but again the design was never frozen, so there was a lot of flexibility remaining in the design.

The End of the Line

Sadly, these plans never reached fruition. The U-ZrH Reactor had its budget cut by 75% in 1971, with cuts to alternate power conversion systems such as the use of thermionic power conversion (30%) and reactor safety (50%), and the advanced Brayton system (completely canceled) happening at the same time. NERVA, which we covered in a number of earlier posts, also had its funding slashed at the same time. This was due to a reorientation of funds away from many current programs, and instead focusing on the Space Shuttle and a modular space station, whose power requirements were higher than the U-ZrH Reactor would be able to offer.

At this point, the AEC shifted their funding philosophy, moving away from preparing specific designs for flight readiness and instead moving toward a long-term development strategy. In 1973 head of the AEC’s Space Nuclear Systems Division said that, given the lower funding levels that NASA was forced to work within, “…the missions which were likely to require large amounts of energy, now appear to be postponed until around 1990 or later.” This led to the cancellation of all nuclear reactor systems, and a shift in focus to radioisotope thermoelectric generators, which gave enough power for NASA and the DoD’s current mission priorities in a far simpler form.

References and Further Reading

Overall Program

SNAP-8, THE FIRST ELECTRIC FROPULSION POWER SYSTEM , Wood et al Aeroget General 1961 https://www.osti.gov/servlets/purl/4837472

Preliminary Reactor and Shield Design for SNAP 8 Power System, Karp et al NASA LRC https://www.osti.gov/servlets/purl/4639751

SNAP 8 Reactor and Shield, Johnson and Goetz, AI 1963 https://www.osti.gov/servlets/purl/4875647

SNAP (SYSTEMS FOR NUCLEAR AUXILIARY POWER) TECHNICAL BRIEFS, PART 4, SNAP 8, Johnson et al AI 1963 https://www.osti.gov/servlets/purl/4475155

SNAP 8 Summary Report, AI Staff 1973 https://www.osti.gov/servlets/purl/4393793

SNAP 8 POWER SYSTEM FOR THE GLOBAL SURVEILLANCE SATELLITE, Stone AI 1961 https://www.osti.gov/servlets/purl/4659315

A SNAP-8 Breadboard System – Operating Experience (poor quality doc) https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19680023766.pdf

Fuel Element Development and Analysis

SNAP 8 Fuel Element Fabrication and Performance Testing, presentation slides, AI 1967 https://www.osti.gov/servlets/purl/4444230

Machining Capability of Hobbing SNAP Cladding Fins, Schrag 1971

https://www.osti.gov/servlets/purl/4201113

SNAP and AI Fuel Summary Report, Lords, Westinghouse 1994

https://www.osti.gov/servlets/purl/10182034

A Document Review to Characterize Atomics International SNAP Fuels Shipped to INEL 1966-1973, Kneff et al, 1995 https://www.osti.gov/servlets/purl/137420

Fuel Matrix Development and Behavior

EFFECT OF SIMULATED FUEL SWELLING ON HYDROGEN PERMEATION OF SNAP 8 FUEL ELEMENTS, Fitzgerald AI 1964 https://www.osti.gov/servlets/purl/4482700

Fuel Clad Development and Behavior

SNAP 8 DRM-1 FUEL ELEMENT END CLOSURE DEVELOPMENT, Dennison et al 1964 https://www.osti.gov/servlets/purl/4467081

HIGH-TEMPERATURE BERYLLIUM CORROSION PROTECTION Phase Report Coating Development and Evaluation, September 22, 1961 to May 15, 1962, Armor Research Foundation staff for AI 1962 https://www.osti.gov/servlets/purl/4160331

HYDROGEN PERMEATION THROUGH SNAP-8 FUEL ELEMENT CLADDING ASSEMBLIES, Enberg AI 1967 https://www.osti.gov/servlets/purl/4540343

Nuclear Design and Analysis

Neutron Scattering from Supporting Structures of SNAP 8 Shield Reactor Package, Friedman et al 1961 https://www.osti.gov/servlets/purl/4648973

The Effect of Temperature and Microstructure of Sintered Beryllium Oxide on the Scattering Cross Section for a SNAP Reactor, Ottewitte AI 1965

https://www.osti.gov/servlets/purl/4596886

SNAP 8 experimental reactor critical experiment, ed Crouter 1964 https://www.osti.gov/servlets/purl/4471079

SNAP 8 SUMMARY S8ER AND S8DS, AI Staff 1966 https://www.osti.gov/servlets/purl/4196263

SNAP 8 POST-SHUTDOWN GAMMA RADIATION APPROXIMATIONS 1972 https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19720009961.pdf

EXPERIMENTAL INVESTIGATION OF REACTOR-LOOP TRANSIENTS DURING SNAP-8 POWER CONVERSION SYSTEM STARTUP 1969 https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19700009964.pdf

EXPERIMENTAL INVESTIGATION OF SNAP-8 SHUTDOWN CHARACTERISTICS 1969 https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19700003783.pdf

EXPERIMENTAL INVESTIGATION OF REACTOR- LOOP TRANSIENTS DURING STARTUP OF A SIMULATED SNAP-8 SYSTEM 1968 https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19680012788.pdf

Primary Coolant System Design and Analysis

EXPERIMENTAL EVALUATION OF SNAP-8 POWER CONVERSION SYSTEM STARTUP 1971 https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19710018616.pdf

STATISTICAL TREATMENT OF HOT CHANNEL FACTORS FOR COMPACT REACTORS, Cohn AI 1963 https://www.osti.gov/servlets/purl/4695946

HIGH-TEMPERATURE BERYLLIUM CORROSION PROTECTION Phas Report Coating Development and Evaluation Phase, September 22, 1961 to May 15, 1962 https://www.osti.gov/servlets/purl/4160331

SNAP-8 CORROSlON PROGRAM QUARTERLY PROGRESS REPORT FOR PERIOD ENDING AUGUST 31, 1963, Savage et al ORNL 1963

https://www.osti.gov/servlets/purl/4650757

SNAP-8 CORROSION PROGRAM SUMMARY REPORT, Savage et al, ORNL 1965 https://www.osti.gov/servlets/purl/4568642

SURVEY OF FISSION- AND CORROSION-PRODUCT ACTIVITY IN SODIUM- OR NaK-COOLED REACTORS, Zwetzig 1969 https://www.osti.gov/servlets/purl/4823059

SNAP-8 REFRACTORY BOILER DEVELOPMENT – CORROSION OF OXYGEN CONTAMINATED TANTALUM IN NaK 1971 https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19710020297.pdf

THERMAL DES I GN OF THE SNAP-8 TANTALUM-STAI NLESS STEEL BOILER 1971 https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19710018379.pdf

SHOCK AND VIBRATION TESTS OF A SNAP-8 NaK PUMP 1971 https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19720004952.pdf

NaK-LUBRI CATED JOURNAL AND THRUST BEARINGS FOR A PUMP-MOTOR ASSEMBLY I N SNAP-8 1972 https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19710020645.pdf

NaK LOOP TESTING OF THERMOELECTRIC CONVERTER MODULES 1973 https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19730015000.pdf

SNAP-8 NaK-PUMP-MOTOR-ASSEMBLY 400 HERTZ START TESTS 1969 https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19700002181.pdf

Component Design, Development, and Analysis

Evaluation of Hastelloy N for SNAP 8 Service, McCoy, Jr and Weir, Jr 1967 (?) https://www.osti.gov/servlets/purl/4503453

SURVEY OF METEOROID PROPERTY AND DISTRIBUTION DATA RELEVANT TO SNAP 8 REACTOR AND SHIELD DESIGN, Harder 1963 https://www.osti.gov/servlets/purl/4726089

SNAP 8 CONTROL DRUM BEARING DEVELOPMENT AND EVALUATION HISTORY, Horton AI 1970 https://www.osti.gov/servlets/purl/4072946

IRRADIATION TEST OF SNAP 8 ACTUATORS, POSITION SENSORS, AND LIMIT SWITCHES, Davies et al 1966 https://www.osti.gov/servlets/purl/4453033

IRRADIATION TEST OF SNAP 8 CANDIDATE SPRING MATERIALS, Cowgill et al AI 1967 https://www.osti.gov/servlets/purl/4332713

Preliminary Design of MK 70 Reaction Turbine for SNAP-8 90 kWe System 1971 https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19710028776.pdf

BALL BEARING DESIGN FOR THE SNAP-8 TURBOALTERNATOR Am MERCURY PUMP 1971 https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19710017434.pdf

Shock and Vibration Test of a SNAP-8 Turboalternator 1971 https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19710018221.pdf

SHOCK, VIBRATION, AND ACCELERATION-LOAD TESTS OF A SNAP-8 MOTOR-DRIVEN LUBRICANT-COOLANT PUMP 1971 https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19710011472.pdf

PERFORMANCE OF THE SNAP-8 LUBHCATION AND COOLANT SUBSYSTEM 1969 https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19690011466.pdf

TRANSFER FUNCTIONS FOR RADIATOR DYNAMICS IN THE SNAP-8 SYSTEM 1969 https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19690005171.pdf

Progress Reports

SNAP 8 Progress Reports

FEBRUARY-APRIL 1965 https://www.osti.gov/servlets/purl/4471031

MAY – JULY 1965 https://www.osti.gov/servlets/purl/4479563

AUGUST-OCTOBER 1965 https://www.osti.gov/servlets/purl/4480195

OCTOBER 1965-JANUARY 1966 https://www.osti.gov/servlets/purl/4470991

Quarterly Progress Reports

JANUARY-MARCH 1962 https://www.osti.gov/servlets/purl/4482704

APRIL-JUNE 1962 https://www.osti.gov/servlets/purl/4480220

OCTOBER – DECEMBER 1962 https://www.osti.gov/servlets/purl/4462892

APRIL-JUNE 1963 https://www.osti.gov/servlets/purl/4474941

FEBRUARY THROUGH APRIL 1964, https://www.osti.gov/servlets/purl/4471082

MAY THROUGH JULY 1964 https://www.osti.gov/servlets/purl/4476769

Progress Reports on SNAP 8 Reactor Development

DECEMBER 1960-MARCH 1961 https://www.osti.gov/servlets/purl/4474629

JULY-SEPTEMBER 1961 https://www.osti.gov/servlets/purl/4468318

OCTOBER-DECEMBER 1961 https://www.osti.gov/servlets/purl/4474971

Bi-Monthly Progress Report, Reactor Development

OCTOBER-NOVEMBER 1960

https://www.osti.gov/servlets/purl/4471247

Facilities (design, building, costs, etc.)

PRELIMINARY SERVICES For SNAP 8 FLIGHT PROTOTYPE TEST FACILITY BUILDING 056 SANTA SUSANA, CALIFORNIA, Bechtel staff for AEC, 1964

https://www.osti.gov/servlets/purl/4609929

SNAP-8 SIMULATOR LOOP MECHANICAL DESIGN 1968 https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19680008991.pdf

INSTRUMENTATION OF A SNAP-8 SIMULATOR FACILITY By James N. Deyo and William T. Wintucky 1968 https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19680009532.pdf

Postoperation Systems Analysis

SNAP-8 POST-SHUTDOWN GAMMA-RADIATION APPROXIMATIONS, Byrn et al Teledyne Brown, date unknown

https://www.osti.gov/servlets/purl/4629234

NAA-53-3 In-Pile Temperature History, Fine et al AI 1963 https://www.osti.gov/servlets/purl/982036

NEUTRON RADIOGRAPHIC INSPECTION OF IRRADIATED SNAP FUEL, Hillig, unknown date (S8DR data) https://www.osti.gov/servlets/purl/4143046

IRRADIATION STABILITY OF SCB-1 COATED HASTELLOY N SNAP 8 FUEL CLADDING EXPERIMENT NAA 77-1 , Enberg et al AI 1965 https://www.osti.gov/servlets/purl/4476471

IRRADIATION STABILITY OF SCB-l COATED HASTELLOY N SNAP 8 FUEL CUDDING EXPERIMENTS NAA 77-2 AND NAA 77-3 Engberg et al, AI 1966

https://www.osti.gov/servlets/purl/4475158

POSTIRRADIATION EXAMINATION OF SNAP 8 CLADDING MATERIAL IRRADIATION EXPERIMENT NAA 77-4, Enberg et al AI 1965

https://www.osti.gov/servlets/purl/4467830

FISSION GAS RELEASE FROM LIGHTLY IRRADIATED SNAP 8 FUEL MATERIALS, Willis et al 1965 https://www.osti.gov/servlets/purl/4474883